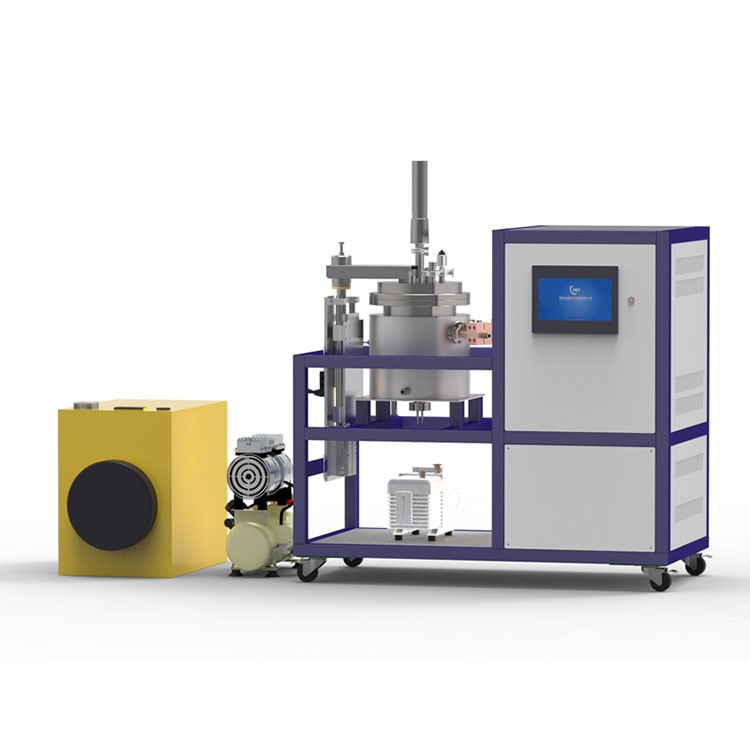

igh Flow Ultra High Purity Hydrogen Gas Generator for Diamond Cultivation

Using a new long-life multi-layer PEM electrolysis unit, no acidic or alkaline solutions are used. The innovative PSA hydrogen drying module ensures the highest level of hydrogen purity and is completely maintenance-free. Automatic checking for internal leaks and continuous control of operating parameters for safety.

LCD touch screen interface provides convenient and simple operation of all functional units.

Mainly used in: hydrogen fuel cell hydrogenation, CVD diamond cultivation, multiple GC centralized gas supply.

Using a new long-life multi-layer PEM electrolysis unit, no acidic or alkaline solutions are used. The innovative PSA hydrogen drying module ensures the highest level of hydrogen purity and is completely maintenance-free. Automatic checking for internal leaks and continuous control of operating parameters for safety.

LCD touch screen interface provides convenient and simple operation of all functional units.

Mainly used in: hydrogen fuel cell hydrogenation, CVD diamond cultivation, multiple GC centralized gas supply.

Using a new long-life multi-layer PEM electrolysis unit, no acidic or alkaline solutions are used. The innovative PSA hydrogen drying module ensures the highest level of hydrogen purity and is completely maintenance-free. Automatic checking for internal leaks and continuous control of operating parameters for safety.

LCD touch screen interface provides convenient and simple operation of all functional units.

Mainly used in: hydrogen fuel cell hydrogenation, CVD diamond cultivation, multiple GC centralized gas supply.

Features and advantages

1. Simple to use and quick to install

2. The maximum flow rate of hydrogen is 4000 cc/min

3. Pressure up to 16 bar (232 psi)

4. Hydrogen purity: 99.99999°/o

5. Standard RS 485, RS 232 and USB

6.PSA hydrogen drying module, maintenance free

7. Self-monitoring procedures to ensure safety

8. Patented electronically controlled high pressure gas-liquid separator

Model parameters:

Model | 4000 | 4000LN |

Electrolysis unit | PEM technology |

|

Drying system | PSA (Pressure Swing Adsorption) / TSA (Temperature Swing Adsorption) |

Hydrogen purity | >99.99999°/o * 1 |

Outlet pressure | 12 bars (174 psi) / 16 bars (232 psi) (optional) |

Hydrogen flow (max) | 4000m l/ min |

Size | 44.5 x 66 x 61.5 cm |

Net weight (anhydrous) | 52 kg | 53 kg |

N2 content | 3 ppm | <1ppm |

Communication | RS232/ RS485/USB |

Supply pressure (min, max) | O bars (O osi),0.5 bar (7.25 osi) |

Flow rate | 0.25l/ h |

Internal water tank capacity | 20L |

Connection Type | IEC320-C14 |

Power supply | 100-240V ac ( 士 10°/o) 50/60 Hz |

Power (max) | 1450W |

Current (5x20mm) | 6.3A (250VAC - T) |

Hydrogen export | 1/ 8” |

Water (inlet, drain) | Push-in connector |